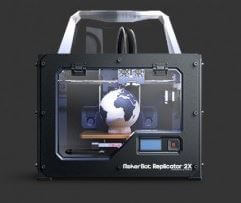

The Dutch 3D printer manufacturer Ultimaker presents the Ultimaker S5, its latest FDM printer, which can be seamlessly integrated into existing workflows with reliable results.

The Features

The Ultimaker S5 has fully integrated hardware, software and material configuration as well as optimal settings especially for professional requirements. These include complete freedom of geometry, industrial-level material properties, reproducibility, high uptime and an integrated workflow. In addition to an optimized touch screen for a better user experience, the printer offers a build volume of 33 x 24 x 30 cm for printing larger objects and a dual extruder. The extruder has a filament flow sensor that automatically stops when the filament has to be filled and then continues the printing process – without affecting the print quality. The print bed is easier to adjust and provides an excellent first layer. During printing, the printing bed is continuously aligned so that unattended use is possible. The Ultimaker S5 offers new applications and prints with a variety of materials, from PLA to advanced engineering plastics such as nylon and PC. In addition, the printer has a closed printing chamber. From autumn 2018 it will be equipped with a print plate made of anodised aluminium.

To the detailed specifications

Source: Ultimaker