The research team around Professor Wenyao Xu of the University at Buffalo presents a method for finding the originator of a 3D-printed object.

“Like fingerprints, no 3D printer is exactly the same.”

This is an excerpt from a new University at Buffalo guided study that describes how to associate a 3D object with its original owner.

PrinTracker

The method is called “PrinTracker” and could ultimately help law enforcement and intelligence agencies track the origin of 3D-printed weapons, counterfeit products and other goods.

“3D printing has many wonderful uses, but it’s also a counterfeiter’s dream. Even more concerning, it has the potential to make firearms more readily available to people who are not allowed to possess them”, says Wenyao Xu, PhD, associate professor of computer science and engineering at the UB’s School of Engineering and Applied Sciences.

Methodology

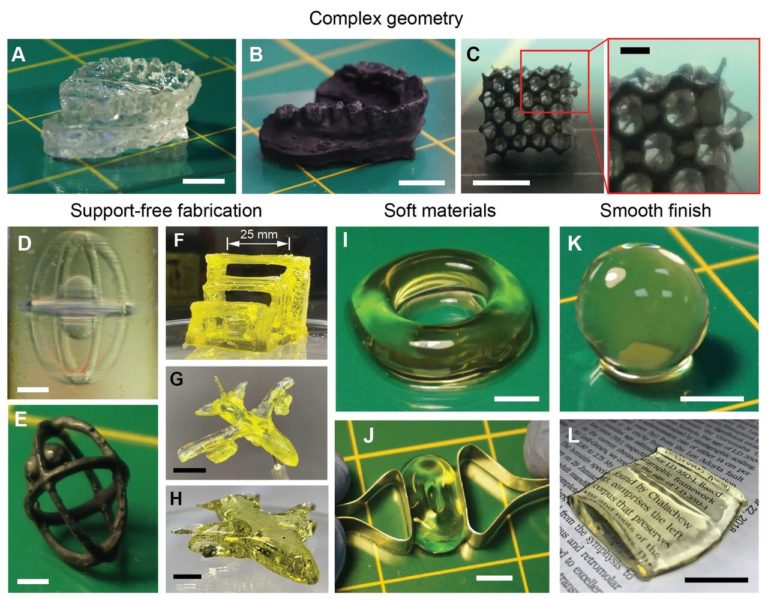

Each layer of a 3D print object contains tiny wrinkles – usually measured in sub-millimeters – so-called in-fill patterns. These patterns shall be uniform. However, the model type of the printer, the filament, the nozzle size and other factors cause slight irregularities in the patterns. The result is an object that does not match its design plan.

For example, the printer is instructed to create an object with half-millimeter in-fill patterns. But the actual object has patterns that deviate 5 to 10 percent from the construction plan. Like a fingerprint for a person, these patterns are unique and repeatable. This allows them to be traced back to the 3D printer. Xu:

“3D printers are built to be the same. But there are slight variations in their hardware created during the manufacturing process that lead to unique, inevitable and unchangeable patterns in every object they print.”

Study

To test PrinTracker, the research team created five door keys from 14 popular 3D printers each – 10 FDM (fused deposition modeling) printers and four stereolithography (SLA) printers.

Using a common scanner, the researchers created digital images of each key. From there, they improved and filtered each image and identified elements of the in-fill pattern. They then developed an algorithm to align and calculate the variations of the individual keys to verify the authenticity of the fingerprint.

After creating a fingerprint database of the 14 3D printers, the researchers were able to transfer the key to their printer in 99.8 percent of cases. 10 months later, they conducted a separate series of tests to determine whether the additional use of the printers would compromise PrinTracker’s ability to match objects to their original device. The results were the same.

The team also conducted experiments with keys damaged in various ways to hide their identity. PrinTracker was 92 percent accurate in these tests. Xu:

“We’ve demonstrated that PrinTracker is an effective, robust and reliable way that law enforcement agencies, as well as businesses concerned about intellectual property, can trace the origin of 3D-printed goods.”

Source: University at Buffalo, Paper