The 3D printer developed by engineers at the Massachusetts Institute of Technology (MIT) produces a Lego brick size component within six minutes. It prints ten times faster than comparable models on the market. The secret lies in the design of the hotend, which works with two systems.

How It Came About

Anastasios John Hart and Jamison Go first analyzed the reasons for the slow speed of commercial 3D printers. They identified three causes: Firstly, the speed of the print head, then the force with which the filament is pressed through the nozzle and finally the heating and melting speed. Then they started to find a new design that didn’t have these three disadvantages.

The Solution

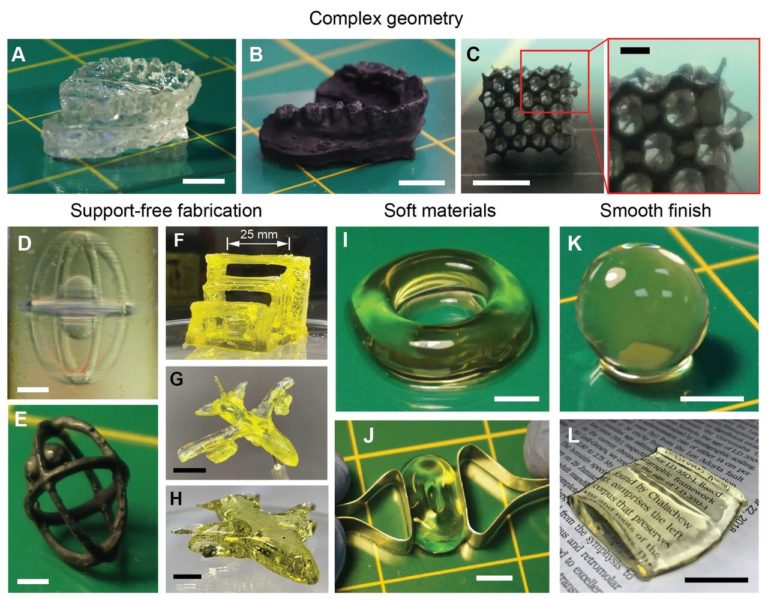

The result is a tiny extruder that pushes the plastic powder out of the die at high speed, and an integrated laser that heats up the material as soon as it leaves the die. When heated in this way, the filament melts faster so that it bonds with the previously applied layer in a flash.

First Demonstrations

The team around mechanics professor Hart has demonstrated the capabilities with various small components such as a spectacle frame, a bevel gear wheel and a miniature version of the MIT dome construction. Hart:

“If I can make prototypes of a small gear or mount in minutes instead of an hour, or a larger component during my breakfast break, I can design, build and test faster.”

Various Application Possibilities

The printer could be installed on a service cart and drive to the customer with the tradesman. According to Hart’s vision, the broken spare part could be produced on site. It could also be used in remote areas in emergency medicine and many other areas. This would save a lot of time and transport effort.

The Next Challenge

The research team printed various complex components with their new printer, all of which were completed within five to ten minutes. But there is another problem that needs to be solved: Because the filament is pressed through the extruder very quickly and at a high temperature, there is hardly any time for the previously printed layer to cure completely. Therefore, the printed part must be actively cooled to avoid distortion. This is a task that the MIT team is currently working on.

Source: MIT