When it comes to consumer electronics and accessories, 3D printing is no longer in its infancy: On Kickstarter, the first DIY turntable is being presented for self-printing and 3D printing of records has already been dared by makers.

Record Player

The first modular record player to print at home is currently being presented by Swiss quality hi-fi manufacturer Lenco in collaboration with Dutch 3D printer manufacturer RepRapUniverse and the Qeske community. The design of the Lenco-MD is inspired by classic Lenco turntables and the community, it consists mainly of renewable resources and can be upgraded.

3D printer KISS200 by RepRapUniverse and classic turntable L-75 by Lenco. Source: Kickstarter. Lenco MD

The modular units are simply rotated onto the three frame legs and are very easy to replace. So every maker can personalize his turntable at will and adapt it to his current needs: With the solar module, for example, you can listen to music outside on a beautiful day. If you prefer wireless connections you can use the Bluetooth module and there is also a speaker module. The electronics are connected with the internal thread of the modules and the modular adapter plate.

Source: Kickstarter. Lenco MD

Depending on previous knowledge, time and desire you can choose between the prefabricated designs or create your own, for example your favorite tonearm or a damping system. There are seven different colors to choose from, including some really bright ones, such as orange, green or red, for those who like it colorful.

The only thing you need is a FFF 3D printer with a minimum size of 33 x 33 x 10 cm. If you have a smaller printer at home, this is no problem, because then you order the turntable and tonearm pre-printed and print the remaining parts at a printer with a build area of at least 20 x 20 x 10 cm. And if you don’t even have a 3D printer or your own is on strike, you can order the whole turntable. It will then be printed and dispatched in Qeske (Holland) by RepRap Universe from PLA. The Basic-Kit is available from 99 euros, the premium package with 40 kits costs 7999 euros.

Vinyl Records

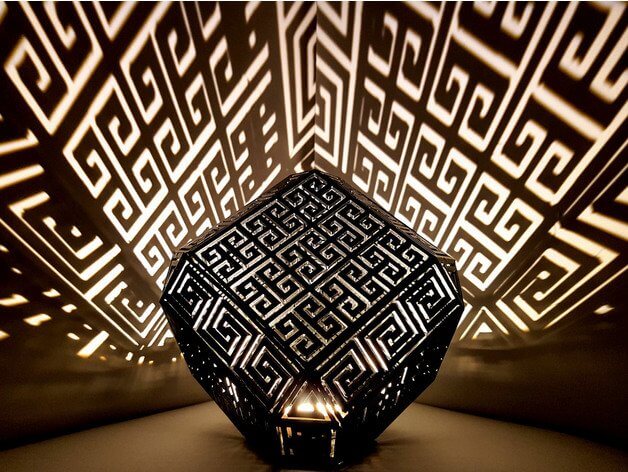

Amanda Ghassaei: Resin Records

Amanda Ghassaei already experimented with 3D printing of records in 2012. Although the audio quality of a resin record does not yet top that of a vinyl record, the songs are definitely recognizable. With some music styles the own sound of such a 3D-printed record might even sound quite exciting.

The 3D modeling for this project was too complex to be done manually, so Amanda developed a processing program to do the conversion automatically. This involves importing raw audio data, performing some calculations to create the geometry of a 12″ dataset, and then exporting that geometry directly into a 3D printable file format.

Source: Amanda Ghassaei

The vinyls were printed with the high-end 3D printer Objet Connex 500 from Stratasys with UV-curing resin. The device prints with tiny resin drops with a resolution of 600 dpi on the x and y axis and 16 microns on the z axis. But even with this precision, the smallest details are at least one or two orders of magnitude larger than those on a real vinyl record. After much experimentation and different parameter settings Amanda was finally able to produce records with a sampling rate of 11 kHz and 5-6 bit resolution per sample. A detailed description of the development process, the code and the downloadable 3D recording files can be found on Instructables.

To the detailed project description

Fred Murphy: Fisher Price Records

Fred Murphy specializes in records for the Fisher Price toy turntable. Instead of listening to carrilon, you can now come up with “Stairway to Heaven”, “The Star Wars Theme” or “You are my Sunshine”. You can order the vinyls or print them yourself. If the latter is the case, you will need to download two OpenSource software packages, Fisher Price Music Editing Software and OpenSCAD.

Source: Instructables, fred27

Depending on how good the print results of your printer are normally, your vinyl results will be as well. Fred Murphy chose a green ABS-like material and transparent “Vero Clear” plastic. Both sound good, but the transparent version convinces him even more optically.