US soldiers will probably be busy collecting plastic waste in the future, because used water bottles, tetrapacks or yoghurt cups are now to be upcycled and used as filament in war zones. The idea came about through cooperation with the U.S. Army Research Laboratory and the U.S. Marine Corps.

FFF Filament

Source: US Army

Dr. Nicole Zander and Capt. Anthony Molnar of the U.S. Navy have made useful filament for 3D printing out of plastic garbage from Polyethylene terephthalate (PET). According to Zander, PET is used in a wide variety of applications, but it has hardly ever been 3D printed so far, because the material has a high melting temperature, crystallinity and absorbs water. Nevertheless, the PET filament was able to withstand tests with conventional filament. In addition, further discarded plastics are to be tested and processed into printing material. After all, recycled polymers can vary in their additives, fillers and dyes.

Advantages and Possible Areas of Application

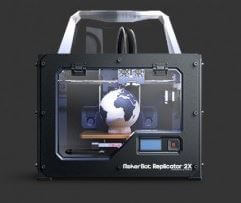

3D printing can be used in a wide variety of military applications: For example, models, spare parts or medical implants are possible. Additive manufacturing offers advantages over traditional manufacturing methods. Examples include freedom of design, time and cost savings. Moreover, the technology is sustainable and can turn unwanted waste into a valuable resource.

MRF

“MRF” stands for “Mobile Recycling Facility” and is to be deployed on site in the near future. In this mobile recycling station, soldiers will be able to print new, useful things from their plastic waste.