With a new green laser with pulse function from TRUMPF, pure copper and precious metals can be printed for the first time.

How it Works

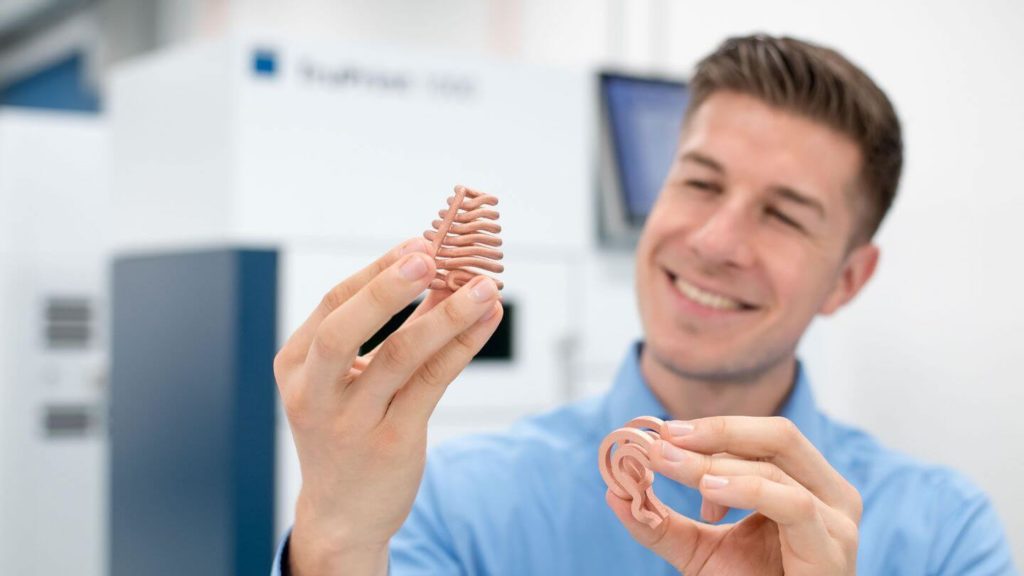

The developers have connected the TruDisk 1020 disk laser to the TruPrint 1000 3D printer for printing gold and copper To the TruPrint 1000

Thomas Fehn, Head of TRUMPF Additive Manufacturing, Sales:

“Conventional systems work with an infrared laser as a beam source. However, its wavelength is too long and cannot weld highly reflective materials such as copper or gold. With the laser light in the green wavelength range this is possible.”

Source: TRUMPF

Fields

According to Fehn, the innovation opens up new possibilities for 3D printing, for example in the electronics industry or the automotive industry. The use of the green laser is particularly attractive in mechanical and plant engineering, because particularly conductive inductors or heat exchangers can be printed from pure copper without any problems. The green laser also has great potential for printing gold for the jewellery industry. Individual single pieces can be produced on demand and at the same time expensive material can be saved. “The 3D printer doesn’t waste expensive gold or silver,” says Fehn. Therefore, printing is often cheaper than milling or casting the piece of jewellery with high material loss.

Source: TRUMPF